Grinding trends in the cement industry Cement Lime Gypsum. 2 Mill orders 2007/2008 according to mill types (OneStone) [3] 4 Types of mills for raw material grinding ...

raw material grinding cement. ... SAM screen can separate the stuff of different size The most important raw materials for making cement are limestone,

Grinding trends in the cement industry Cement Lime Gypsum. 10 Combination grinding system with roller press. ... 23 Raw material mill .

Loesche Mills for cement raw material. 2 Cement raw material has been almost exclusively ground in roller mills (vertical airswept grinding mills) since the second ...

The grinding of raw material of cement manufacturing has broad effect on the homogeneity of feed raw material into rotation clinker furnace. Learn More.

JK Cement Ltd of India has contracted ThyssenKrupp Polysius to supply three new grinding plants equipped with POLYCOM highpressure grinding rolls. The...

raw material grinding cement industry – CGM Mine Machine . Ball grinding mill, roller grinding mill for slag, coal, fly . Alternative raw materials (ARM) like ...

Why Cement Raw Material Grinding is Important News Date: 15:53:33. Proper analysis and identification of raw materials are essential to achieving the best ...

Cement Facts: History of Cement: ... Raw Materials Proportioning Grinding. ... has to be treated as an individual raw material component and the appropriate ...

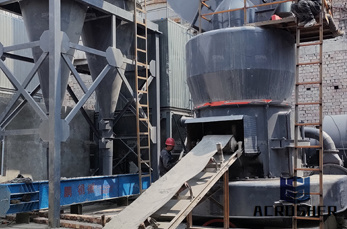

8 YRS Zhengzhou Jiangtai Heavy Industrial Machinery Co., Ltd. China (Mainland) | Manufacturer, Trading Company. Supplier Assessments:

Raw material grinding is one of the processes used to manufacture cement of highest quality.

Raw material grinding in a cement plant. Raw material grinding is a critical mechanical operation predominantly determining the sizing of equipment in a cement .

CEMENT INDUSTRY Output of a Seminar ... A cement production plant consists of the following three processes. 1. ... Figure 4 Dry process raw material grinding system5

Material ground consists of limestone, cement rock, ... know how unquestionably qualify Grate Discharge grinding for the Cement Industry. RAW CEMENT GRINDING.

Ball mills are still used in 12–13 % of all raw material grinding applications, such as the ... also been used for grinding cement raw material. ...

How cement is made and history of ... The first step is to quarry the principal raw materials, mainly ... The finely ground raw material or the slurry is fed into ...

Raw material preparation. From the quarry to raw meal feeding ... the raw material needed for the cement production ... of the raw material grinding

The raw material preparation stage of cement manufacture results in the production of a rawmix that ... both for cement grinding and for grinding hard raw ...

CEMENT RAW MATERIALS PLANT SIZES. The coordinates of the grinding table diameter and number of rollers can be read off from the table. The x .

Raw Material Cement, Wholesale Various High Quality Raw Material Cement Products from Global Raw Material Cement Suppliers and Raw Material Cement Factory,Importer ...

cement (building material) Encyclopedia Britannica . cement, in general, adhesive substances of all kinds, but, in a narrower sense, the binding materials used in ...

According to statistics, over 60% cement plant power will be consumed to grind materials in dry process cement production line. Among which, over 30% is used for raw ...

Portland Cement Manufacturing ... raw material processing operations differ somewhat for ... water is added to the raw mill during the grinding of the raw ...

Finished cement is produced by finely grinding together around 95% ... of raw material used worldwide for cement manufacture is very ... CEMENT RAW MATERIALS ...

WhatsApp)

WhatsApp)